HVAC Technician Tool List: A Comprehensive Guide (2025)

Essential HVAC tools encompass levels, pliers, tin snips, flashlights, core removal tools, and hex-head drivers; PDF checklists aid inventory and maintenance.

HVAC technicians require a diverse toolkit, ranging from basic hand tools to sophisticated diagnostic equipment, ensuring efficient and safe system maintenance and repair. A comprehensive HVAC tool list PDF serves as an invaluable resource for both seasoned professionals and those entering the field, detailing necessary implements. These lists typically categorize tools – hand tools like screwdrivers and pliers, diagnostic tools such as multimeters and leak detectors, and specialized equipment like tube benders and vacuum pumps.

Furthermore, a well-maintained PDF checklist streamlines tool inventory, preventing lost or misplaced items, and facilitates routine maintenance checks. Accessing these resources online provides technicians with readily available guidance, promoting professionalism and adherence to industry standards. Utilizing such lists enhances productivity and minimizes downtime, ultimately benefiting both the technician and the client.

Basic Hand Tools for HVAC Technicians

Essential hand tools include screwdriver kits, ratcheting screwdrivers, nut drivers, pliers (lineman’s, diagonal, needle-nose), and crimpers; PDF lists detail these necessities.

Screwdriver Sets: Types and Applications

A comprehensive screwdriver set is foundational for any HVAC technician. These sets commonly include slotted, Phillips, Torx, and square-drive screwdrivers, catering to diverse fastener types encountered in HVAC systems. Ratcheting screwdrivers significantly enhance efficiency, allowing for continuous turning without repositioning. Technicians benefit from insulated screwdrivers for electrical safety, crucial when working with live circuits.

Different applications demand specific screwdriver types; for instance, precision screwdrivers are vital for delicate control board work. PDF checklists often categorize screwdrivers by size and drive type, ensuring technicians have the correct tool readily available. Investing in a high-quality set with durable handles and hardened tips extends tool lifespan and improves performance. Regularly inspecting screwdriver tips for wear and tear is essential for safe and effective operation.

Pliers: Lineman’s, Diagonal, and Needle-Nose

HVAC technicians rely heavily on a versatile selection of pliers. Lineman’s pliers, with their robust cutting and gripping jaws, are essential for heavier tasks like wire manipulation and component securing. Diagonal cutters (dikes) excel at cleanly snipping wires and leads, while needle-nose pliers provide precision for working in confined spaces. Channel-lock pliers offer adjustable gripping power for various pipe and fitting sizes.

A well-organized PDF checklist should detail each plier type and its specific applications. Technicians should prioritize pliers with comfortable, insulated grips for safety and reduced fatigue. Regular inspection for worn or damaged cutting edges is crucial. Maintaining a dedicated plier holder ensures quick access and prevents loss, contributing to efficient workflow and job site organization.

Nut Drivers and Ratcheting Screwdrivers

Nut drivers and ratcheting screwdrivers are indispensable for efficient fastener manipulation in HVAC systems. A comprehensive set of nut drivers, covering both standard and metric sizes, is vital for accessing various components. Ratcheting screwdrivers significantly speed up repetitive fastening tasks, reducing strain and improving productivity. Interchangeable bit sets expand the screwdriver’s versatility, accommodating different screw head types.

An effective PDF checklist should specify the required range of sizes for both nut drivers and screwdriver bits. Technicians should verify that ratcheting mechanisms function smoothly and that bits are securely held. Regularly inspecting for wear and tear, and replacing worn tools, ensures reliable performance. Proper organization within a tool bag or box is key for quick access during service calls.

Tin Snips and Shears for Ductwork

Tin snips and shears are crucial for modifying and installing ductwork, requiring precision cutting of sheet metal. Straight-cut snips excel at making clean, straight lines, while curved snips are ideal for navigating tighter bends and contours. Aviation snips, offering various blade configurations, provide versatility for different cutting tasks. Durable shears are essential for trimming and shaping flexible ducting.

A detailed PDF checklist should confirm the presence of both straight and curved snips, alongside aviation snips with appropriate blade types. Technicians must ensure blades are sharp and free from nicks to prevent tearing or distortion of the metal. Safety precautions, like wearing gloves, should be emphasized. Regular inspection and sharpening maintain optimal cutting performance and tool longevity.

Diagnostic Tools: Identifying HVAC Issues

PDF checklists confirm multimeters, manifold gauges, leak detectors, and combustion analyzers are present for accurate system diagnosis and efficient troubleshooting.

Multimeters: Electrical Testing Fundamentals

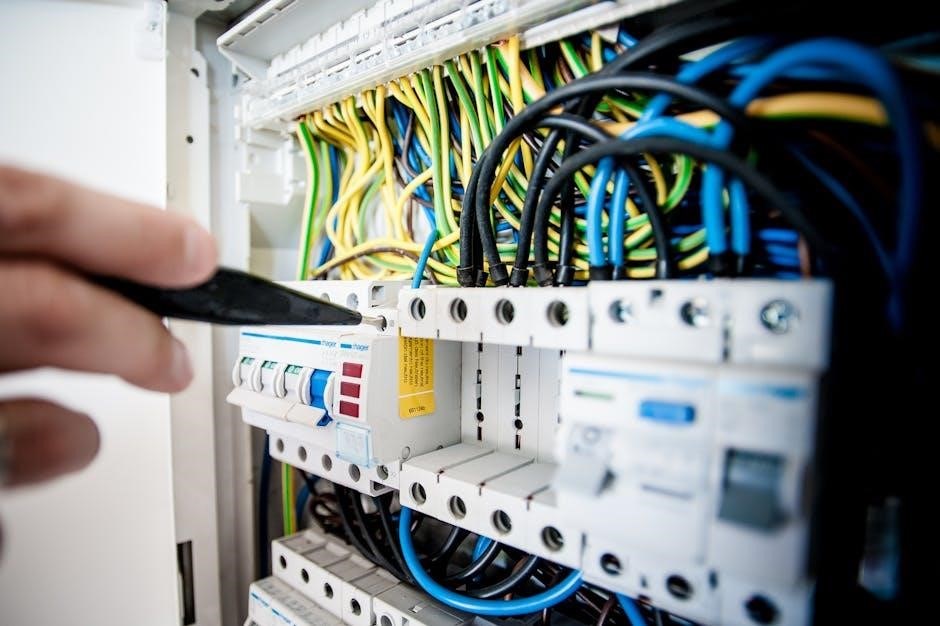

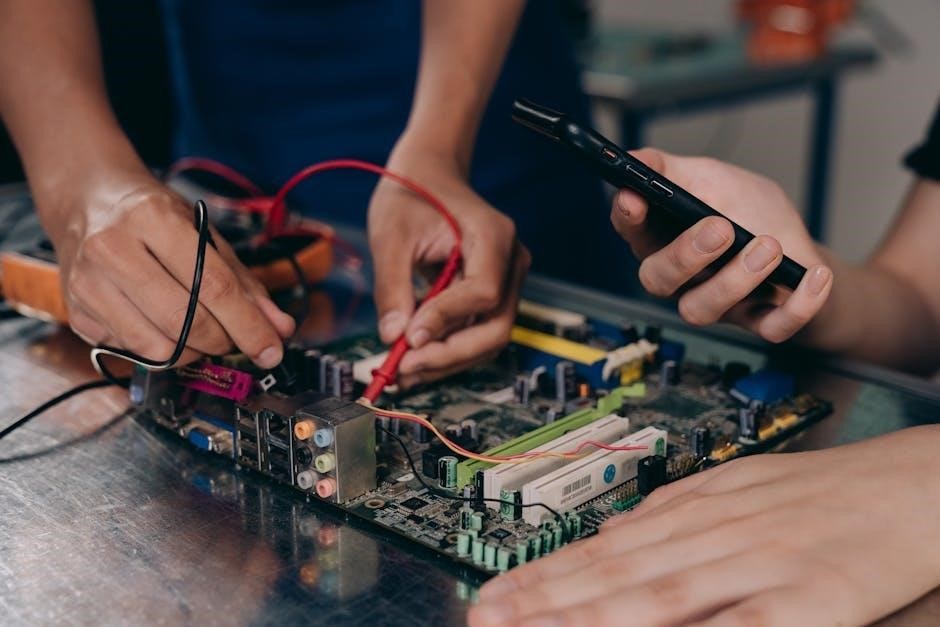

Multimeters are foundational for HVAC diagnostics, verifying voltage, current, and resistance within circuits. A comprehensive HVAC technician tool list PDF should detail multimeter specifications – auto-ranging, true RMS, and input impedance are crucial considerations. Technicians utilize these tools to pinpoint electrical faults, assess motor windings, and confirm proper component operation.

PDF checklists ensure the multimeter is calibrated and functioning correctly before each use, alongside verifying the condition of test leads. Understanding electrical testing fundamentals, as reinforced by a detailed tool list, is paramount for safe and accurate troubleshooting. Proper multimeter usage prevents damage to equipment and ensures technician safety, making it a non-negotiable item on any HVAC tool inventory.

Manifold Gauge Sets: Refrigerant Pressure Measurement

Manifold gauge sets are indispensable for accurately measuring refrigerant pressures – crucial for diagnosing cooling and heating system performance. A detailed HVAC technician tool list PDF should specify set features like hose lengths, connection types, and gauge accuracy. Technicians rely on these tools to determine superheat, subcooling, and identify refrigerant leaks or restrictions.

PDF checklists should include regular leak checks of gauge connections and hose integrity; Proper use, guided by a comprehensive tool list, ensures accurate readings and prevents refrigerant loss. Understanding pressure-temperature relationships, as detailed in accompanying documentation, is vital. A well-maintained manifold gauge set is essential for efficient system diagnosis and repair, guaranteeing optimal HVAC performance.

Refrigerant Leak Detectors: Electronic and Bubble-Based

Refrigerant leak detectors, both electronic and bubble-based, are critical for pinpointing refrigerant escapes – a key component detailed in any thorough HVAC technician tool list PDF. Electronic detectors offer sensitivity and quick response, while bubble solutions are cost-effective for larger leaks. A comprehensive PDF should outline calibration procedures for electronic units and proper application techniques for bubble solutions.

PDF checklists should mandate regular battery checks for electronic detectors and solution freshness for bubble leak detectors. Accurate leak detection minimizes refrigerant loss, protects the environment, and ensures system efficiency. Proper training on detector usage, as referenced in the tool list’s supplemental materials, is paramount for reliable results and safe operation.

Combustion Analyzers: Efficiency and Safety Checks

Combustion analyzers are indispensable for evaluating furnace and boiler performance, ensuring safe and efficient operation – a vital inclusion in any detailed HVAC technician tool list PDF. These tools measure flue gas components like oxygen, carbon monoxide, and temperature, revealing combustion efficiency and potential hazards. A comprehensive PDF should detail proper sensor maintenance and calibration procedures for accurate readings.

PDF checklists should emphasize regular analyzer checks and adherence to manufacturer guidelines. Accurate combustion analysis minimizes fuel consumption, reduces emissions, and prevents carbon monoxide poisoning. Training on interpreting analyzer data, often linked within the tool list’s resources, is crucial for effective troubleshooting and safe system adjustments.

Specialty HVAC Tools

Specialty tools, like tube benders and vacuum pumps, are crucial; a detailed HVAC technician tool list PDF should outline their specific applications and maintenance.

Tube Benders and Flaring Tools

Tube benders are indispensable for accurately shaping refrigerant lines without kinking, ensuring optimal system performance. Different types exist – lever-style, rotary, and electric – each suited for varying tubing sizes and materials. A comprehensive HVAC technician tool list PDF should detail the appropriate bender for copper, aluminum, and steel.

Flaring tools create secure, leak-proof connections by expanding and sealing the tube ends. Proper flaring is critical; a flawed flare can lead to refrigerant loss and system failure. The PDF checklist should include various flaring tool types (standard, eccentric, and 45-degree) and emphasize the importance of using the correct die size. Regular calibration and inspection, as noted in the tool list, are vital for maintaining accuracy and preventing costly errors.

Core Removal Tools: Accessing Refrigerant Systems

Core removal tools are essential for safely accessing refrigerant systems to recover, evacuate, or charge. These tools allow technicians to quickly and efficiently remove the Schrader valve core without damaging the valve body; A detailed HVAC technician tool list PDF should specify various core removal tool types – standard, self-sealing, and universal – and their compatibility with different valve stems.

The PDF checklist should also highlight the importance of having replacement cores readily available, categorized by size and type. Proper handling and storage, as outlined in the document, prevent contamination and ensure a leak-tight seal upon reinstallation. Regular inspection of the tool for damage is crucial, guaranteeing safe and effective operation during refrigerant servicing.

Vacuum Pumps and Recovery Machines

Vacuum pumps and recovery machines are critical for maintaining refrigerant system integrity and adhering to environmental regulations. A comprehensive HVAC technician tool list PDF must detail pump CFM (cubic feet per minute) ratings and horsepower, alongside machine recovery capacity in pounds. The PDF should emphasize the necessity of oil changes and filter replacements for optimal pump performance, alongside leak checks on recovery machine hoses.

Furthermore, the checklist should include proper procedures for refrigerant recovery, ensuring compliance with EPA guidelines. It’s vital to document refrigerant type and quantity recovered. Regular calibration and maintenance schedules, as detailed in the PDF, extend equipment lifespan and ensure accurate operation, preventing contamination and promoting responsible refrigerant handling.

Safety Equipment: Protecting the HVAC Technician

HVAC tool list PDFs should prioritize safety: glasses, gloves, headlamps, and lockout/tagout tools are essential for technician protection during service.

Safety Glasses and Gloves

Safety glasses are paramount, shielding technicians from debris during ductwork modification, refrigerant handling, and electrical work – a crucial item on any HVAC tool list PDF. Impact-resistant lenses are preferred, meeting ANSI Z87.1 standards for reliable protection.

Gloves offer vital protection against cuts, abrasions, and chemical exposure. Heavy-duty work gloves are essential for handling sheet metal and navigating tight spaces. Furthermore, refrigerant-resistant gloves are non-negotiable when working with cooling systems, preventing frostbite and chemical burns. A comprehensive HVAC tool list PDF should specify glove types for various tasks, ensuring technicians are adequately prepared for every scenario. Proper glove selection minimizes risks and promotes a safe working environment.

Headlamps and Flashlights: Working in Dark Spaces

Headlamps and flashlights are indispensable for HVAC technicians frequently working in dimly lit areas like attics, crawl spaces, and equipment closets – a critical inclusion on any detailed HVAC tool list PDF. A quality headlamp offers hands-free illumination, enhancing efficiency and safety during repairs and installations.

Look for models with adjustable brightness settings and long battery life. Durable, water-resistant flashlights are also essential for outdoor work or in damp environments. A HVAC tool list PDF should specify both types, emphasizing the importance of reliable lighting for accurate diagnostics and safe operation. Proper illumination minimizes errors and prevents accidents in challenging work conditions, ensuring technician well-being and quality workmanship.

HVAC-Specific Safety Tools (e.g., Lockout/Tagout)

A comprehensive HVAC tool list PDF must include specialized safety equipment beyond standard PPE. Lockout/Tagout (LOTO) devices are paramount for de-energizing equipment during maintenance, preventing accidental startup and protecting technicians from electrical hazards. Voltage testers verify power is off before work begins.

Refrigerant recovery equipment requires specific safety tools to prevent releases. Proper labeling and storage containers are also vital. A detailed HVAC tool list PDF should outline these requirements, ensuring compliance with safety regulations. Prioritizing safety isn’t just about avoiding accidents; it’s about fostering a responsible work environment and protecting both personnel and the environment.

Digital Resources & PDF Checklists

HVAC tool list PDFs online offer comprehensive inventories; checklists streamline tool management, ensuring technicians have necessary equipment for efficient and safe operations.

Finding Comprehensive HVAC Tool List PDFs Online

Locating detailed HVAC technician tool list PDFs is surprisingly accessible in today’s digital landscape. Numerous industry websites, manufacturer pages, and technical school resources offer downloadable checklists. These PDFs typically categorize tools into essential groups: basic hand tools, diagnostic equipment, and specialized instruments.

A quick online search using keywords like “HVAC tool list PDF,” “HVAC technician tool checklist,” or “HVAC equipment inventory” will yield a wealth of options. Many professional HVAC associations also provide members-only access to more detailed and customized lists. Remember to verify the source and date of the PDF to ensure it reflects current industry standards and best practices. Regularly updated lists are crucial, as tools and technologies evolve.

Utilizing Checklists for Tool Inventory and Maintenance

HVAC tool list PDFs aren’t just for initial purchasing; they’re invaluable for ongoing inventory management and preventative maintenance. Implementing a checklist system, derived from a comprehensive PDF, ensures technicians have all necessary tools before each job, minimizing delays and maximizing efficiency.

Regularly comparing physical tool inventories against the checklist identifies missing or damaged items. Furthermore, checklists can incorporate maintenance schedules – noting calibration dates for diagnostic tools, or lubrication reminders for hand tools. This proactive approach extends tool lifespan, reduces repair costs, and enhances workplace safety. Evolution highlights checklists foster collaboration and adaptation, crucial for successful HVAC teams.

Tool Policy and Management for HVAC Companies

A robust tool policy, informed by a detailed HVAC tool list PDF, is vital for company success and technician accountability, ensuring proper tool care.

Importance of a Clear Tool Policy

A well-defined tool policy, often referencing a comprehensive HVAC technician tool list PDF, is paramount for any successful HVAC company. It establishes clear expectations regarding tool ownership, maintenance, and accountability. This minimizes loss, damage, and unauthorized use of expensive equipment.

Furthermore, a detailed policy streamlines tool inventory management, ensuring technicians have the necessary resources for each job. Utilizing a PDF checklist derived from the master tool list facilitates regular audits and identifies missing or broken items promptly. This proactive approach reduces downtime and improves service efficiency.

Beyond operational benefits, a clear policy fosters a culture of responsibility among technicians, promoting professionalism and respect for company assets. It also protects the company legally by outlining procedures for tool-related incidents and liabilities.