The 6.7 Cummins EGR delete is a popular modification to enhance engine performance, reduce maintenance, and lower exhaust gas temperatures. It involves removing the EGR system to improve efficiency and power.

1.1 What is an EGR Delete?

An EGR (Exhaust Gas Recirculation) delete is a modification that removes the EGR system from a 6.7 Cummins engine. This process involves eliminating the components responsible for recirculating exhaust gases back into the engine. By doing so, it aims to reduce soot buildup, lower exhaust gas temperatures (EGTs), and improve overall engine performance. The EGR delete typically includes installing block-off plates on the EGR cooler and intake manifold to prevent exhaust gas flow. This modification is popular among diesel truck owners seeking enhanced efficiency and reduced maintenance needs.

1.2 Why Perform an EGR Delete on a 6.7 Cummins?

Performing an EGR delete on a 6.7 Cummins engine is primarily done to enhance performance, reduce maintenance, and improve fuel efficiency. The EGR system, designed to reduce emissions, can lead to soot buildup in the intake system, which may require frequent cleaning. By eliminating the EGR, drivers can enjoy lower exhaust gas temperatures (EGTs), reduced soot accumulation, and potentially better mileage. This modification is particularly popular among diesel truck owners seeking to optimize their engine’s operation and longevity.

Benefits of EGR Delete for 6.7 Cummins Engines

Deleting the EGR system on a 6.7 Cummins engine enhances performance, reduces soot buildup, lowers exhaust temperatures, and improves fuel efficiency, benefiting overall engine operation and longevity.

2.1 Improved Engine Performance

Performing an EGR delete on a 6.7 Cummins engine significantly boosts performance by eliminating the restrictive flow of exhaust gases. This modification allows for increased horsepower and torque, as the engine operates more efficiently without the EGR system’s limitations. Drivers often notice smoother acceleration and a more responsive throttle, making it ideal for both daily driving and heavy-duty applications. The removal of soot-filled exhaust gases from the intake system also contributes to cleaner combustion and reduced engine strain, further enhancing overall performance and reliability.

2.2 Reduced Maintenance Costs

Removing the EGR system significantly reduces maintenance costs by eliminating soot buildup in the intake manifold and engine components. This minimizes the need for frequent cleaning or replacement of parts like the EGR cooler and valves. Without the EGR, there’s less risk of clogging and corrosion, leading to lower repair expenses and extended engine longevity. This makes the EGR delete a cost-effective solution for maintaining your 6.7 Cummins engine over time.

2.3 Lower Exhaust Gas Temperatures (EGTs)

Performing an EGR delete on a 6.7 Cummins engine can significantly lower exhaust gas temperatures (EGTs). By eliminating the recirculation of exhaust gases, the engine operates cooler, reducing thermal stress. Users have reported EGTs dropping to around 650°F during highway driving and as low as 350°F when parked. This reduction minimizes the risk of overheating and potential engine damage, contributing to improved overall engine health and longevity.

2.4 Increased Fuel Efficiency

An EGR delete can improve fuel efficiency by reducing the engine’s workload. Without recirculating exhaust gases, the engine operates more efficiently, especially under load. Many 6.7 Cummins owners report a 1-2 MPG increase, as the engine no longer battles the cooling and flow restrictions of the EGR system. Cooler operating temperatures and smoother combustion contribute to better mileage, making this modification a practical choice for those seeking enhanced fuel economy without sacrificing performance.

Legal and Environmental Considerations

EGR deletes may violate emissions regulations, leading to legal penalties. Removing the EGR system increases emissions, potentially harming the environment and affecting air quality standards.

3.1 Understanding Emissions Regulations

Emissions regulations, set by the EPA, aim to reduce pollutants like nitrogen oxides (NOx) and particulate matter. The EGR system is mandated to lower NOx emissions by recirculating exhaust gases. Tampering with or removing the EGR system, such as through an EGR delete, violates these regulations and can result in legal consequences, including fines. It’s important to understand these rules before proceeding with any modifications to ensure compliance and avoid penalties.

3.2 Potential Legal Consequences of EGR Delete

Performing an EGR delete on your 6.7 Cummins may result in legal consequences due to violations of EPA emissions standards. Tampering with emissions systems is illegal under the Clean Air Act and can lead to significant fines. Modified vehicles may fail inspections or attract scrutiny during audits. Additionally, dealerships may void warranties if they detect unauthorized modifications. Understanding these risks is crucial before proceeding with an EGR delete to avoid legal and financial repercussions.

3.3 Environmental Impact of EGR Removal

Removing the EGR system increases nitrogen oxide (NOx) emissions and particulate matter, contributing to air pollution. The EGR system reduces NOx by recirculating exhaust gases, lowering combustion temperatures. Without it, emissions rise, harming environmental quality. This modification can lead to failing emissions tests and may contribute to climate change. Drivers should weigh performance gains against the environmental impact and regulatory compliance, as EGR removal contradicts emissions standards aimed at reducing pollution.

EGR Delete Kit Options for 6.7 Cummins

EGR delete kits for the 6.7 Cummins are designed to improve performance and reduce maintenance. Popular options include Flashark and SPELAB kits, offering comprehensive solutions.

4.1 Popular EGR Delete Kits

Popular EGR delete kits for the 6.7 Cummins include Flashark and SPELAB kits, known for their reliability and comprehensive instructions. These kits are designed to eliminate the EGR system, improving engine performance and reducing maintenance. They often include block-off plates, hoses, and hardware for a seamless installation. DIY-friendly options are available, catering to both experienced mechanics and enthusiasts. These kits are widely recommended for their durability and effectiveness in enhancing engine efficiency and power output while adhering to aftermarket standards.

4.2 DIY vs. Pre-Fabricated Kits

DIY EGR delete kits offer customization and cost savings but require fabrication skills and tools, such as bandsaws and sanders, to create block-off plates. Pre-fabricated kits, like Flashark and SPELAB, provide pre-made components for easier installation. They include block-off plates, hoses, and hardware, reducing fabrication time. DIY setups are ideal for experienced enthusiasts, while pre-fabricated kits suit those seeking convenience and reliability. Both options aim to eliminate EGR-related issues but cater to different skill levels and preferences.

4.3 Essential Components of an EGR Delete Kit

An EGR delete kit typically includes block-off plates to seal the EGR ports, exhaust components like v-band clamps and adapters, and hoses or connectors to reroute exhaust gases. Additional hardware such as bolts, fasteners, and gaskets ensures a secure installation. Some kits may also include tuning components to optimize engine performance post-delete. These parts are designed to eliminate EGR-related issues, improve engine efficiency, and reduce soot buildup in the intake system, making them essential for a successful modification.

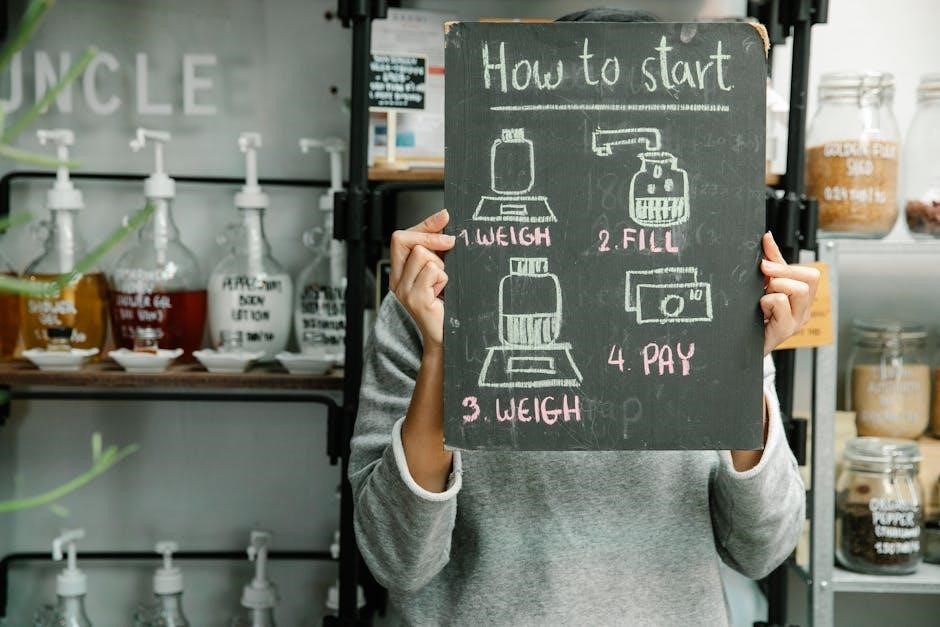

Step-by-Step Installation Guide

Disconnect batteries, drain coolant, and remove the intake assembly. Follow detailed instructions to remove EGR components, install block-off plates, and reconnect hoses for a complete EGR delete.

5.1 Preparation: Disconnecting Batteries and Draining Coolant

Begin by disconnecting the negative battery cables to ensure safety. Drain the coolant from the radiator’s lower corner to prevent spills during disassembly. Remove the passenger-side inner fender liner for access. These steps are crucial for a safe and efficient EGR delete installation, minimizing potential damage and ensuring proper component removal.

5.2 Removing the Intake Assembly and EGR Cooler

Next, remove the intake assembly to access the EGR system. Carefully disconnect the hoses and electrical connectors attached to the intake. Once the intake is out, focus on the EGR cooler. Remove the mounting bolts securing the cooler and gently pull it free from its position. Disconnect all associated hoses and sensors. Handle these components with care to avoid damage. Proper removal ensures a clean installation of the EGR delete kit and block-off plates.

5.3 Installing Block Off Plates and EGR Delete Kit

Install the block-off plates over the EGR ports, ensuring a tight seal to prevent leaks. Use high-quality gaskets or sealants for proper fitment. Next, attach the EGR delete kit to the engine, aligning it with the intake and exhaust ports. Secure the kit using the provided hardware, tightening bolts evenly. Double-check all connections for leaks and ensure the system is properly sealed. This step is crucial for maintaining engine performance and preventing potential issues post-installation.

5.4 Reconnecting Hoses and Securing Components

Reconnect the intake and exhaust hoses, ensuring they are securely fastened to prevent leaks. Tighten all clamps and fittings properly. Verify that the block-off plates and EGR delete kit are securely bolted in place. Double-check all connections for snugness and alignment. Use torque specifications for bolts to avoid over-tightening. Finally, inspect the system for any signs of leaks or loose components before proceeding to the next step.

5.5 Reinstalling Intake Assembly and Other Components

Once the EGR delete kit is installed, carefully reinstall the intake assembly, ensuring proper alignment and secure fastening. Reattach all components, such as the mass airflow sensor and intake ducting, to their original positions. Double-check that all connectors and hoses are properly reconnected. Use new gaskets or seals where necessary to ensure a leak-free installation. Finally, verify that all components are securely fastened and aligned before proceeding to the next step.

5.6 Final Checks and Testing

After reinstalling all components, inspect for leaks around block-off plates and connections. Clear any fault codes using a scanner and ensure the EGR system is disabled. Start the engine, allowing it to run for a few minutes to check for leaks or unusual noises. Monitor exhaust gas temperatures and fuel efficiency improvements. Take the vehicle for a test drive to ensure smooth operation and verify that all systems function properly. Address any issues promptly before finalizing the installation.

Tools and Materials Needed

Essential tools include a bandsaw, belt/disc sander, wrenches, and sockets. Materials like 1/8-inch aluminum for block-off plates and gaskets are required for a proper installation.

6.1 Essential Tools for the Job

The installation requires a bandsaw or similar cutting tool, wrenches, sockets, screwdrivers, and pliers. A torque wrench ensures proper bolt tightening. Additional tools like a belt/disc sander may be needed for custom block-off plates. A rivet gun is useful for certain components. Ensure all tools are readily available to streamline the process and avoid delays during the EGR delete installation.

6.2 Materials Required for Block Off Plates

Aluminum sheets (1/8-inch thick) are ideal for creating block-off plates. Trace the EGR housing to cut 2-inch diameter circles. Sand or grind edges for smoothness. Ensure plates fit securely to prevent leaks. Use durable materials to withstand engine heat and pressure. Properly seal the plates to maintain engine performance and efficiency after the EGR delete installation.

6.3 Additional Hardware and Fasteners

Stainless steel bolts, gaskets, and v-band clamps are essential for securing components. Ensure all fasteners are grade 8 or higher for durability. Use high-temperature silicone gaskets to prevent leaks. V-band clamps are crucial for connecting the crossover elbow and exhaust system. Properly tighten all hardware to avoid loose connections. Consult a parts list or manual for specific bolt sizes and torque specifications to ensure a secure and leak-free installation.

Post-Installation Checks and Maintenance

Monitor engine performance, check for leaks, and ensure all connections are secure. Regularly inspect hoses and gaskets to maintain proper sealing and functionality of the EGR delete system.

7.1 Monitoring Engine Performance

After installing the EGR delete, monitor engine performance closely to ensure optimal operation. Check for error codes using a tuner or scan tool, as the EGR delete may trigger warnings; Observe exhaust gas temperatures (EGTs) to confirm they remain within safe limits. Note improvements in power and responsiveness. Use tools like the Edge monitor to track fuel efficiency and verify MPG gains. Proper installation and tuning are critical to avoid issues and maximize performance benefits, ensuring the engine runs smoothly and efficiently.

7.2 Checking for Leaks and Proper Sealing

After installing the EGR delete, inspect all connections for leaks to ensure proper sealing. Check the block off plates, EGR cooler ports, and exhaust connections for any signs of leakage. Use a soapy water solution or a pressure test kit to detect gaps or improper seals. Ensure all bolts and clamps are tightened to the manufacturer’s specifications. Any leaks can lead to reduced performance and potential damage, so thorough inspection is critical for maintaining engine reliability and efficiency.

7.3 Updating Engine Tuning for EGR Delete

After completing the EGR delete, updating the engine tuning is essential to optimize performance. A custom tune ensures the engine computer adapts to the removal of the EGR system. This prevents error codes, improves fuel injection timing, and enhances overall engine efficiency. Proper tuning also helps maintain proper exhaust gas flow and prevents issues like reduced power or rough engine operation. Consulting a professional tuner is recommended to ensure the tune is calibrated correctly for your specific setup.

Troubleshooting Common Issues

Troubleshooting after an EGR delete involves diagnosing error codes, checking for leaks, and addressing reduced power or performance issues. Proper installation and tuning are key to avoiding problems.

8.1 Diagnosing Error Codes Post-Installation

After installing an EGR delete, common error codes may appear, such as P0401 (EGR system flow insufficient) or P0201 (injector circuit malfunction). These codes are triggered by the absence of EGR flow. Using a tuner or code-blocking device, like the Edge CTS, can help eliminate these codes. Ensure all connections are secure and properly sealed. If codes persist, check for leaks or improper installation. Correcting these issues is essential for maintaining engine performance and avoiding potential damage.

8.2 Addressing Reduced Power or Performance

Reduced power post-EGR delete can stem from improper installation or tuning. Ensure all connections are tight and verify that the block-off plates are correctly sealed. Check for intake leaks, as these can significantly impact performance. Updating the engine tuning with a performance-oriented calibration is crucial to optimize power output. If issues persist, inspect the air filter and fuel injectors for cleanliness. Addressing these factors will help restore and potentially enhance your engine’s performance and efficiency. Consulting a professional tuner may be necessary for optimal results;

8.3 Fixing Leaks or Incorrect Installations

Leaks or improper installations can lead to reduced performance or engine issues. Inspect block-off plates and gaskets for tightness and proper sealing. Use a smoke test to identify any leaks in the intake or exhaust system. Re-check all connections, ensuring they are secure and aligned correctly. If leaks persist, replace damaged gaskets or reseal joints with high-temperature sealant. Verify installation steps against the guide to ensure no components were missed or improperly fitted. Addressing these issues promptly will restore proper engine function and prevent further complications.

Performance Gains After EGR Delete

The EGR delete unlocks significant performance potential by increasing horsepower, torque, and engine responsiveness. It also ensures smoother operation and reduces soot buildup in the intake system.

9.1 Increased Horsepower and Torque

Removing the EGR system on a 6.7 Cummins engine typically results in a noticeable increase in horsepower and torque. By eliminating the EGR restriction, exhaust gases no longer recirculate, allowing the engine to breathe more freely. This reduction in backpressure enhances combustion efficiency, leading to improved power output. Many drivers report a smoother and more responsive throttle, especially during towing or heavy loads. The EGR delete also reduces soot buildup, further contributing to a cleaner and more efficient engine operation.

9.2 Smoother Engine Operation

Performing an EGR delete on a 6.7 Cummins engine often results in smoother engine operation; By eliminating the EGR system, exhaust gases no longer recirculate, reducing soot buildup in the intake system. This leads to a cleaner intake manifold and cylinder heads, which minimizes carbon deposits and promotes consistent airflow. The engine runs more evenly, with less likelihood of rough idling or stuttering. Additionally, lower exhaust gas temperatures contribute to a cooler and more stable operating environment, enhancing overall engine smoothness and reliability.

9.3 Reduced Soot Buildup in Intake System

Removing the EGR system significantly reduces soot accumulation in the intake system. Normally, exhaust gases recirculated by the EGR contain soot, which can coat the intake manifold and cylinders. By eliminating the EGR, these gases are directed out of the exhaust system instead, minimizing soot buildup. This results in a cleaner intake system, reduced carbon deposits, and improved airflow, which contributes to better engine performance and longevity over time.

Fuel Efficiency Improvements

The 6.7 Cummins EGR delete can improve MPG by reducing exhaust gas recirculation, lowering EGTs, and minimizing soot buildup, leading to enhanced fuel efficiency and engine performance.

10.1 Measuring MPG Gains

After performing a 6.7 Cummins EGR delete, many drivers report improved fuel efficiency. MPG gains typically range from 1 to 2.5 miles per gallon, depending on driving conditions and engine tuning. Proper measurement requires consistent testing over various driving scenarios to ensure accurate results. Lower EGTs and reduced soot buildup contribute to these improvements. Regular monitoring and adjustments to tuning can further optimize fuel economy, helping drivers maximize the benefits of their EGR delete modification.

10.2 Optimizing Fuel Economy Post-Delete

Optimizing fuel economy after an EGR delete involves fine-tuning engine performance and driving habits. Custom engine tuning is essential to maximize efficiency gains. Maintaining consistent speeds and avoiding aggressive acceleration can improve MPG. Upgrading to a high-flow air intake and exhaust system further enhances fuel economy. Regular monitoring of engine parameters using gauges ensures optimal operation. Proper maintenance, such as cleaning or replacing filters, also supports sustained efficiency improvements, helping you achieve the best possible fuel economy post-delete.

FAQ: Common Questions About 6.7 Cummins EGR Delete

Frequently asked questions about the 6.7 Cummins EGR delete include whether it voids warranties, if it can be done DIY, and how long installation typically takes.

11.1 Will an EGR Delete Void My Warranty?

Performing an EGR delete on your 6.7 Cummins can void your vehicle’s warranty. Dealerships may detect the modification, leading to denied claims. EGR systems are emissions-controlled, and tampering with them violates regulations. Check with your manufacturer or dealership to understand the risks and warranty terms before proceeding.

11.2 Can I Perform the EGR Delete Myself?

Performing an EGR delete on your 6.7 Cummins can be done yourself if you have mechanical skills and the right tools. It’s recommended for experienced DIYers, as improper installation can cause issues. Ensure you follow detailed instructions and have knowledge of cooling system procedures and engine components. While it saves money, improper execution may lead to performance problems or leaks. Proceed with caution and consider professional help if unsure.

11.3 How Long Does the Installation Process Take?

The installation of a 6.7 Cummins EGR delete typically takes 4-8 hours, depending on mechanical skill and familiarity with the engine. DIY installations may take longer due to learning curves, while experienced technicians can complete it faster. Detailed preparation, such as draining coolant and disconnecting components, adds to the time. Plan a full day for the process to ensure proper execution and avoid rushing, as mistakes can lead to costly repairs.

The 6.7 Cummins EGR delete is a proven modification to enhance performance, reduce maintenance, and improve efficiency. Proper installation and regular upkeep ensure optimal results and engine reliability.

12.1 Final Thoughts on EGR Delete for 6.7 Cummins

The 6.7 Cummins EGR delete is a modification that enhances performance, reduces soot buildup, and lowers EGTs, offering a cleaner and more efficient engine operation. While it provides clear benefits, it’s important to consider legal and environmental implications. Proper installation and high-quality components are essential to avoid issues. Owners should weigh the advantages against potential risks and ensure compliance with local regulations. Regular maintenance and monitoring post-installation are key to maintaining engine health and performance.

12.2 Encouragement for Proper Installation and Maintenance

Proper installation and regular maintenance are crucial for maximizing the benefits of an EGR delete. Ensure all components are securely fastened, and follow detailed instructions to avoid leaks or damage. Regularly inspect hoses, connections, and block-off plates to maintain system integrity. Keep the engine tuned for optimal performance and monitor EGTs to prevent overheating. By adhering to these practices, you’ll enjoy improved efficiency, reduced soot buildup, and a longer engine lifespan. Always consult a professional if unsure about any step.