Pellet stoves offer a modern‚ efficient heating solution for homes. Understanding their operation‚ from initial setup to regular maintenance‚ ensures optimal performance and longevity.

Registering your product online at www.usstove.com is crucial‚ alongside saving your purchase receipt for potential claims. Read the entire manual before use!

These stoves utilize compressed wood or biomass pellets‚ providing a consistent and controllable heat source. Proper operation‚ as detailed in the manual‚ is key.

1.1 What is a Pellet Stove?

Pellet stoves represent a significant advancement in home heating technology‚ offering a blend of convenience‚ efficiency‚ and environmental responsibility. Unlike traditional wood stoves‚ pellet stoves utilize compressed wood or biomass material formed into small‚ cylindrical pellets. These pellets are automatically fed into a burn pot‚ where they are ignited and combusted to generate heat.

The operation of a pellet stove is largely automated‚ controlled by a thermostat and a sophisticated system that regulates pellet feed rate and airflow. This automation provides consistent heat output and minimizes the need for manual intervention. Before operating‚ reading the entire manual is paramount‚ as it details specific features and safety protocols for your model.

Furthermore‚ registering your product online at www.usstove.com is a vital step‚ ensuring access to support and warranty services. The Integra Pellet Stove‚ for example‚ showcases this technology‚ with detailed instructions covering electrical components and operational procedures. Understanding these components is crucial for safe and efficient use.

1.2 Benefits of Using a Pellet Stove

Pellet stoves offer numerous advantages over traditional heating methods‚ making them an increasingly popular choice for homeowners. A key benefit is their high efficiency‚ converting a greater percentage of fuel into usable heat compared to wood stoves or fireplaces. This translates to lower heating costs and reduced environmental impact.

Operationally‚ pellet stoves are remarkably convenient. Automatic pellet feed systems eliminate the need for frequent refueling‚ and precise temperature control ensures consistent comfort. However‚ proper operation hinges on understanding your specific model; therefore‚ reading the manual before use is non-negotiable.

Moreover‚ pellet stoves produce minimal smoke and creosote‚ reducing the risk of chimney fires and improving indoor air quality. Registering your product at www.usstove.com provides access to vital updates and support. The Lily Iris pellet stove exemplifies these benefits‚ offering a clean and efficient heating solution‚ detailed in its comprehensive user manual.

1.3 Safety Precautions

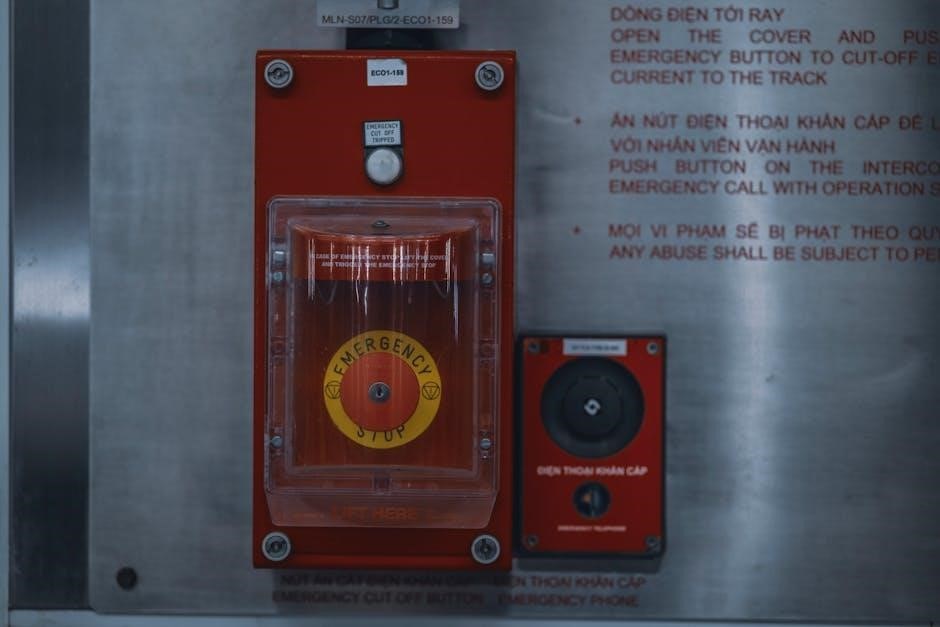

Pellet stove operation‚ while convenient‚ demands strict adherence to safety guidelines. It is against federal regulations to operate the heater inconsistently with instructions‚ emphasizing the importance of the user manual. Always ensure proper ventilation to prevent carbon monoxide buildup‚ a potentially fatal hazard.

Regular maintenance is paramount. Accumulated ash must be removed frequently‚ as excessive buildup can impede airflow and compromise efficiency. The ash content of the fuel directly impacts cleaning frequency; premium grade fuel produces less ash. Never dispose of ash near combustible materials.

Furthermore‚ keep flammable objects clear of the stove’s exterior and ensure the surrounding area is well-ventilated. Registering your product allows access to safety updates. Before any maintenance or cleaning‚ always disconnect the power supply. Familiarize yourself with emergency shutdown procedures as outlined in the manual‚ prioritizing safety above all else.

Understanding Pellet Fuel

Pellet fuel quality significantly impacts stove performance. Standards‚ like those from P.F.I.‚ dictate fines content‚ bulk density‚ size‚ and ash content for optimal combustion.

Using compliant fuel ensures efficient heating and minimizes maintenance‚ contributing to a safe and reliable pellet stove experience.

2.1 Pellet Fuel Standards (P.F;I.)

P.F.I. (Pellet Fuels Institute) standards are crucial for ensuring consistent and efficient pellet stove operation. These standards define acceptable parameters for pellet fuel quality‚ directly impacting combustion efficiency‚ emissions‚ and stove maintenance requirements. Adhering to these guidelines promotes optimal performance and longevity of your heating system.

Key standards include fines content‚ limited to a maximum of 1% passing through a 1/8-inch screen. Excessive fines can cause clumping and impede airflow. Bulk density must be at least 40 pounds per cubic foot‚ ensuring sufficient fuel mass for consistent burning. Pellet size should range from 1/4 to 5/16 inches in diameter and no longer than 1.5 inches‚ facilitating smooth feeding into the stove.

Finally‚ ash content is limited to 1% for premium grade pellets‚ minimizing residue buildup and reducing cleaning frequency. Utilizing fuel meeting these P.F.I. standards guarantees a cleaner‚ more efficient‚ and trouble-free pellet stove experience; Always prioritize certified pellets for peak performance and safety.

2.1;1 Fines Content

Fines content‚ referring to the amount of fine particles within pellet fuel‚ significantly impacts pellet stove operation. P.F.I. standards dictate a maximum of 1% fines‚ measured by material passing through a 1/8-inch screen. High fines content can lead to several operational issues‚ hindering efficient combustion and potentially damaging your stove.

Excessive fines accumulate within the stove’s burn pot‚ creating a dense layer that restricts airflow. This restricted airflow results in incomplete combustion‚ producing more smoke‚ reducing heat output‚ and increasing creosote buildup in the chimney. Furthermore‚ fines can clump together‚ causing feeding problems and potentially jamming the auger system.

Regularly inspecting your pellet fuel for excessive dust or powder is crucial. Choosing certified pellets ensures adherence to P.F.I. standards‚ minimizing fines content and promoting optimal stove performance. Maintaining low fines levels translates to cleaner burning‚ reduced maintenance‚ and a more reliable heating experience.

2.1.2 Bulk Density

Bulk density is a critical characteristic of pellet fuel‚ directly influencing a pellet stove’s performance and efficiency. P.F.I. standards require a minimum bulk density of 40 pounds per cubic foot. This measurement indicates how tightly packed the pellets are‚ impacting feed rates and combustion quality.

Higher bulk density means more fuel mass per volume‚ leading to a more consistent and reliable fuel feed. Stoves are calibrated based on a specific bulk density; fuel with significantly lower density may result in underfeeding‚ causing inconsistent heat output and potential flame-out issues. Conversely‚ excessively high density can strain the auger motor.

Low bulk density often indicates poorly compressed pellets‚ increasing the proportion of fines and reducing overall heating value. Selecting pellets meeting the P.F.I. standard ensures consistent density‚ promoting efficient combustion‚ minimizing maintenance‚ and maximizing the heat output from your pellet stove. Proper fuel density is key to optimal operation.

2.1.3 Pellet Size

Pellet size is a standardized specification crucial for consistent and efficient operation within a pellet stove. The P.F.I. (Pellet Fuels Institute) standard dictates that pellets should range in diameter from 1/4 inch to 5/16 inch (approximately 6.35mm to 7.94mm). Furthermore‚ the maximum length of a pellet is specified as 1.5 inches (12 mm).

Adhering to these dimensions ensures proper flow through the stove’s auger and burn pot. Pellets outside this size range can cause feeding issues‚ leading to inconsistent heat output or even stove malfunctions. Oversized pellets may jam the auger‚ while undersized pellets contribute to increased fines and dust.

Consistent pellet size promotes uniform combustion‚ maximizing heat release and minimizing creosote buildup. Utilizing pellets that meet the P.F.I. standard guarantees compatibility with your stove’s feeding mechanism and combustion chamber‚ contributing to reliable performance and reduced maintenance requirements. Correct size is vital for smooth operation.

2.1.4 Ash Content

Ash content in pellet fuel significantly impacts stove operation and maintenance frequency. The P.F.I. standard specifies a maximum ash content of 1% for premium grade pellets. Lower ash content translates to less frequent cleaning of the stove’s burn pot‚ heat exchanger‚ and ash pan.

Higher ash content leads to quicker ash accumulation‚ potentially reducing airflow and diminishing heating efficiency. Excessive ash can also contribute to clinkering‚ where ash fuses into hard masses‚ obstructing the burn pot and requiring more intensive cleaning; The ash content directly determines how often you’ll need to empty the ash pan.

Regularly emptying the ash pan is crucial for maintaining optimal stove performance and preventing potential issues. Choosing premium grade pellets with low ash content minimizes cleaning efforts and ensures consistent‚ efficient heating. Monitoring ash buildup and adhering to the manufacturer’s cleaning schedule are essential for safe and reliable operation.

Initial Setup and Installation

Proper installation is vital for safe and efficient operation. Register your product online and retain your receipt for warranty claims. Always prioritize reading the entire manual!

3.1 Registering Your Product

Registering your new pellet stove is a straightforward yet incredibly important step in the initial setup process. This action safeguards your investment and ensures access to crucial support and warranty services should the need ever arise. The manufacturer‚ US Stove‚ specifically directs customers to register their product online through their official website: www.usstove.com.

This online registration process typically requires information found on your stove’s data plate and your original proof of purchase. Save your receipt alongside your registration confirmation; this documentation is essential for validating any future warranty claims. Failing to register your stove could potentially complicate or even invalidate your warranty coverage.

Beyond warranty benefits‚ registration allows the manufacturer to keep you informed about important product updates‚ safety notices‚ and potential recalls. It also contributes to their understanding of product usage‚ helping them improve future designs and offerings. Don’t delay – register your pellet stove today for peace of mind and continued support!

3.2 Reading the Manual (Important!)

Before operating your pellet stove‚ a thorough reading of the accompanying instruction manual is absolutely essential. The manual serves as a comprehensive guide to understanding your specific model’s features‚ functions‚ and safety protocols. It’s not merely a suggestion; it’s a critical step for safe and efficient operation.

The manual details everything from initial setup and proper pellet fuel selection to routine maintenance and troubleshooting common issues; It outlines specific warnings and cautions regarding operation‚ including federal regulations concerning wood heater usage. Ignoring these guidelines could lead to malfunctions‚ safety hazards‚ or voided warranties.

The instruction manual is an integral part of the product itself. Pay close attention to sections covering electrical components‚ stove functionality‚ and cleaning procedures. Familiarize yourself with the control panel and understand the meaning of any displayed error codes. Prioritizing this step ensures a safe‚ enjoyable‚ and long-lasting heating experience with your new pellet stove.

Operating Your Pellet Stove

Stove switching on requires following the manufacturer’s specific instructions. Manual pellet loading involves filling the hopper‚ ensuring consistent fuel supply for reliable‚ efficient heating.

Refer to your manual for detailed guidance on these crucial operational steps.

4.1 Stove Switching On

Initiating your pellet stove involves a specific sequence‚ detailed within your user manual. Prior to the first start-up‚ and regularly thereafter‚ ensure the hopper is adequately filled with approved pellet fuel. The initial start-up often requires a priming cycle‚ where the auger delivers pellets to the burn pot to establish a base fuel bed.

Most models feature a power switch‚ typically located on the control panel. Upon activation‚ the stove will initiate a self-diagnostic check‚ verifying the functionality of essential components like the auger motor‚ combustion blower‚ and exhaust system. Observe the control panel for any error codes‚ referencing the manual for troubleshooting guidance.

The stove will then enter an ignition phase‚ utilizing an electric igniter to ignite the pellets. During this phase‚ the combustion blower operates at a lower speed to facilitate proper airflow. Once ignition is confirmed‚ the stove will gradually increase the combustion blower speed and pellet feed rate to achieve the desired heat output. Always monitor the initial burn cycle to ensure stable combustion and proper venting. Refer to section 09.4.1 for further details.

4.2 Manual Pellet Loading

While many pellet stoves feature automatic pellet feed systems‚ understanding manual loading procedures is crucial for troubleshooting or in situations where automatic feed malfunctions. The hopper‚ the reservoir holding the pellets‚ requires periodic refilling. Always ensure the stove is powered off before manually adding pellets to prevent damage to the auger or other components.

Carefully lift the hopper lid and slowly pour pellets into the hopper‚ avoiding overfilling. Overfilling can cause jamming within the auger system. Ensure the pellets are dry and free from debris to maintain optimal combustion efficiency. If the auger becomes jammed‚ do not attempt to dislodge it with force.

Consult your user manual for specific instructions on clearing auger jams‚ as improper handling can cause significant damage. After manually loading pellets‚ restart the stove and allow it to cycle through its ignition sequence. Monitor the pellet feed rate to confirm the auger is functioning correctly. Section 09.4.2 provides additional guidance on this process.

Maintenance and Cleaning

Regular maintenance is paramount for safe and efficient pellet stove operation. Ash removal is a primary task‚ with frequency dictated by fuel quality and burn rate – premium grade fuel produces less ash (maximum 1%). Accumulated ash restricts airflow‚ diminishing heating performance and potentially causing malfunctions.

Always allow the stove to cool completely before removing ash. Empty the ash pan frequently‚ disposing of ashes in a metal container with a tight-fitting lid‚ away from combustible materials. Inspect the burn pot and air passages regularly‚ removing any obstructions.

Periodically clean the heat exchanger‚ following the manufacturer’s instructions in your manual. A clean heat exchanger maximizes heat transfer. Check and clean the venting system annually to prevent creosote buildup‚ a fire hazard. Proper cleaning ensures optimal performance and extends the lifespan of your pellet stove.